SAW Touch Panel

-

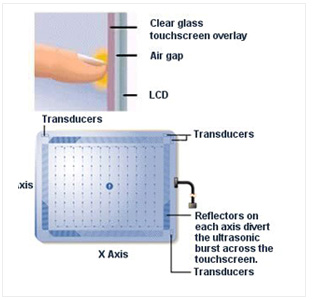

The surface acoustic wave method sends ultrsonic pulses across the surface of a glass layer and detects where they are disturbed.

The surface acoustic wave method sends ultrsonic pulses across the surface of a glass layer and detects where they are disturbed.

The parts are

• a glass layer over the front of the LCD with a flexible bond to the LCD,

• piezo-electric crystals bonded to the glass, to put out a sound pulse travelling across the glass face,

• reflectors to redirect the sound back to the crystals, where the sound wave is re-converted to an electric charge.

When the finger touches the glass, some of the sound is absorbed or redirected. The separate sensors see this effect differently, so the position of the touch can be calculated.

-

SAW is an interesting technology with some special advantages and issues. Unlike resistive or capacitive, there is no coating on the glass: the brightness is hardly affected and wear is not an issue. However the glass must not be rigidly mounted or the mounts will absorb all the sound energy, leaving nothing to get back to the sensor. The very flexible seals required where it meets the cabinet are generally too flexible for washdown applications. In dirty applications, these seals may cake with dirt and eventually need to be cleaned or replaced. On the positive side, we have seen high temperature steelmaking slag embed itself in the glass with no serious impact on the operation of the touch sensor.

In the past, the sensors were large, overhanging the LCD dimensions, and the crystals were mounted on the front, a nuisance for the face seals. Most sensors are now made with rear-face crystals and so-called "beveled" glass: the overhang is reduced, but still present, because the crystal must clear the edge of the LCD. This presents special problems for the LCD/touch mounting system. Our unique "screw adjust" open frames let us deal with those adjustments easily in the field.